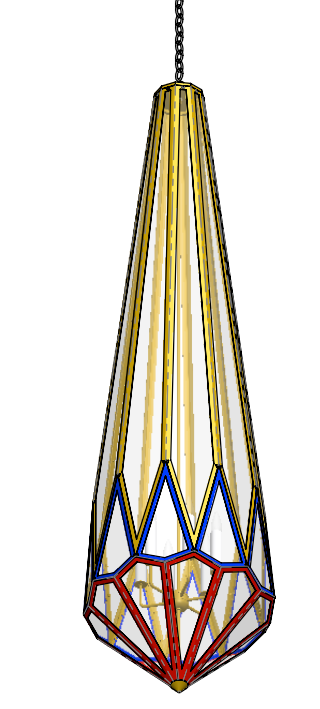

Ten-Sided Entry Pendant

Designed a one-of-a-kind Six-Light Entry Pendant with custom relamping method

Originally conceived as a “stained glass”-style construction, I redesigned the upper and lower sections to have a screwed-together front half and back half; the blue diamond-shaped segment were soldered to the upper frame, which helped provide rigidity but came with its own difficulties.

1:1 paper template

Model with three sections colored differently

Final fixture, suspended and electrified

Photo credit: Remains Lighting

Project Breakdown

Since we didn’t have the capabilities to make a large stained-glass-style assembly, I devised a method to make the fixture from large bent sheet metal sections. This required custom glazing bars (which hold the glass in place)

The design didn’t allow for a traditional door for relamping, so I designed a custom relamping method that dropped the lower “Cage” – which also had to be removable to be safely packed and transported.

Custom Drop Tube Assembly

Primarily used for Relamping

Removable for packing/shipping

Fabrication and Testing

Fabricator applying heat to solder from top to bottom to affix the custom Glazing Bars with Glass-Holding Tabs to the upper frame, blocking light leaks and adding rigidity to the assembly

Dropping a heavy weight to ensure that soldered connection will not fail