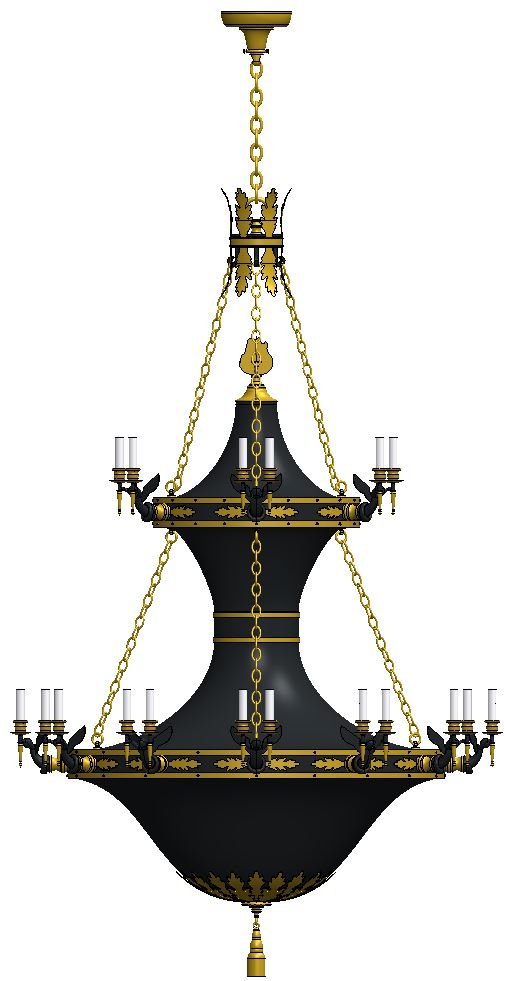

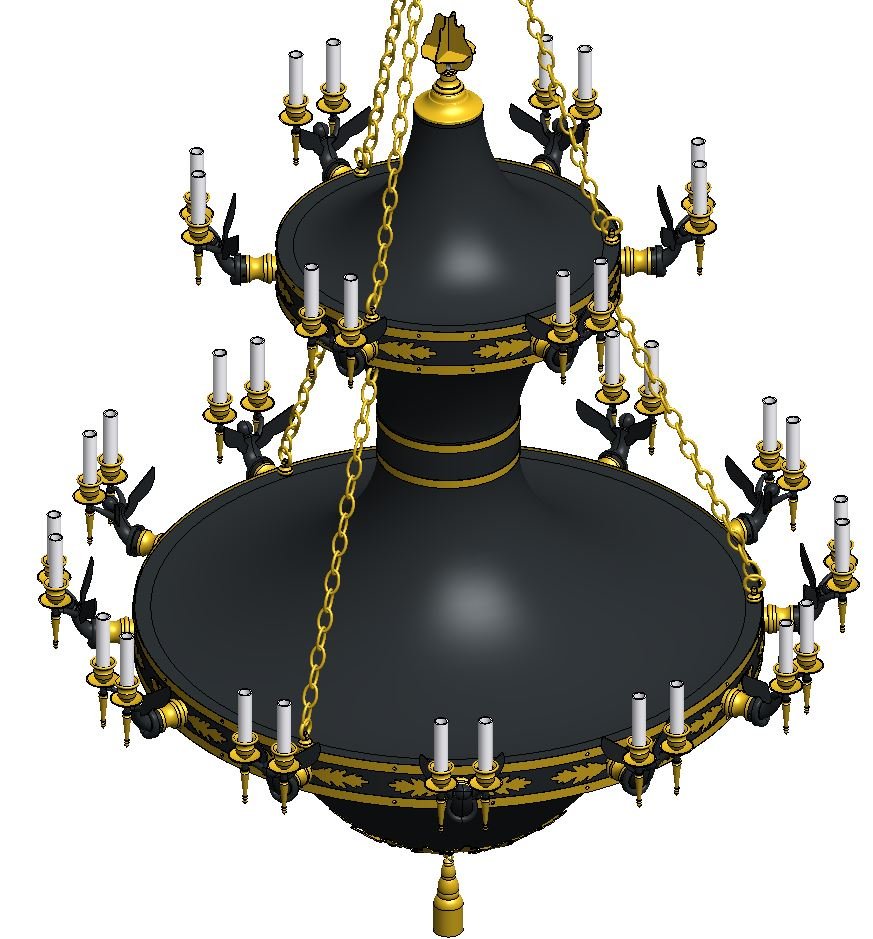

Angel Chandelier

Chandelier made from custom aluminum spinnings, cast bronze cherubs, and rolled and welded rings of brass and steel – over 1,000 components in total.

Started out as one complete assembly, but had to be disassembled to fit through client’s double doors. Required redesign of internal assembly and installation instructions.

Final Assembly

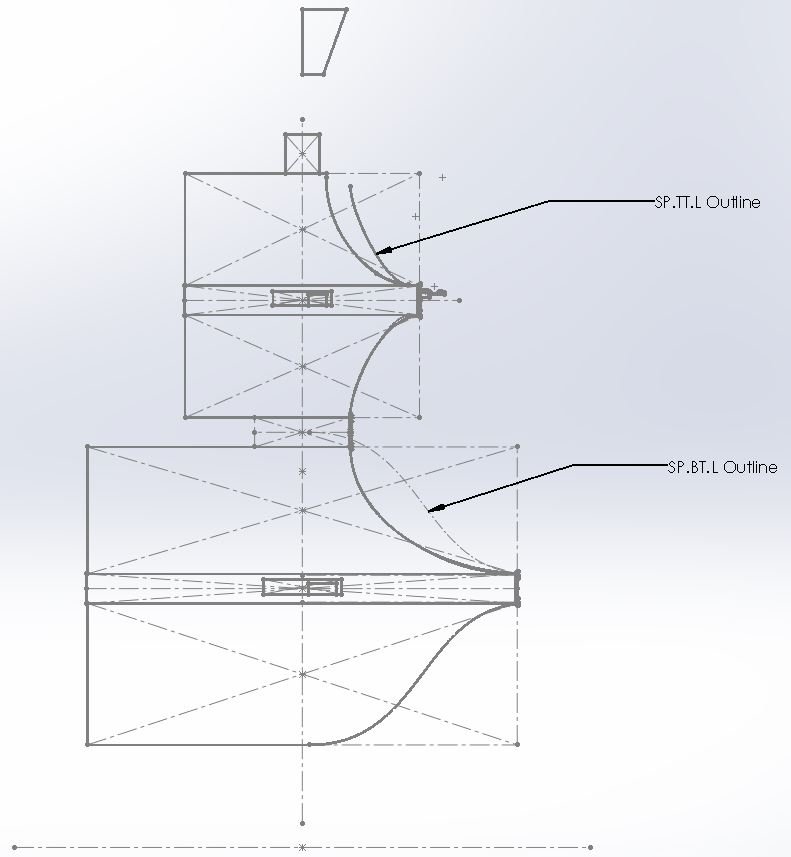

Final SolidWorks model

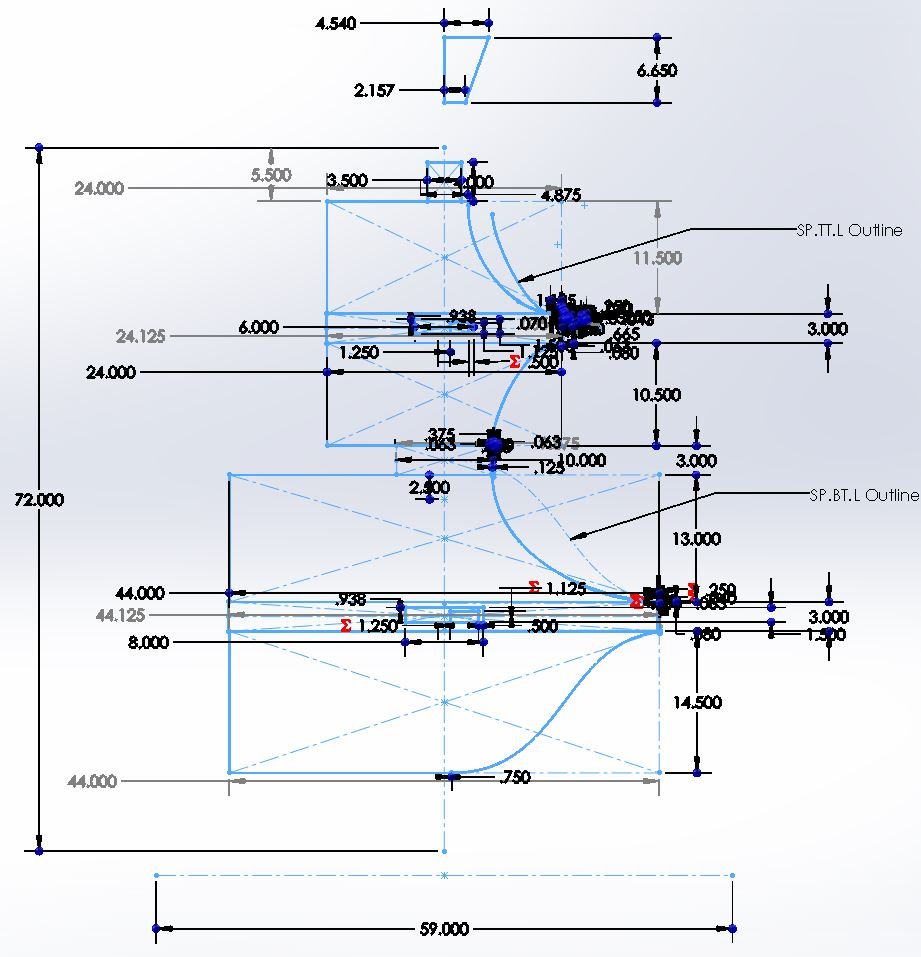

SolidWorks sketch showing "Resilient Modeling Strategy" skeleton, which was used to create every Part model. This method ensured that parts would fit together.

RMS Skeleton with dimensions. Note the "SP.TT.L Outline" and "SP.BT.L Outline" calllouts, which were the reflections of their corresponding lower Spinning outline. The vendor made a mold of the larger profile, made two aluminum Spinnings, then cut down the mold to make the smaller profile Spinning.